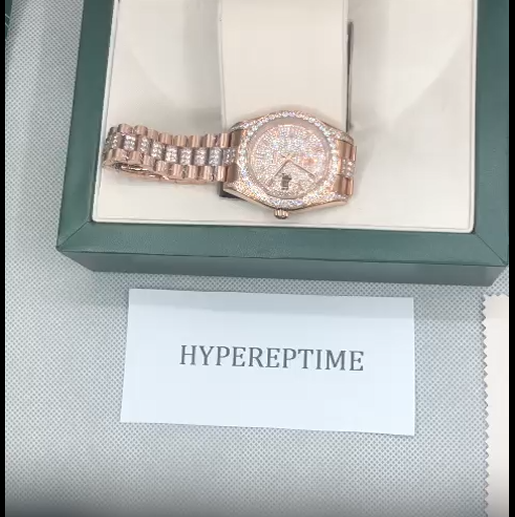

Most people think replica watches are cheap knockoffs made in dark rooms with poor tools and zero attention to detail.

The reality?

Modern high-end replicas are produced in organized workshops using advanced machinery, skilled technicians, and processes that closely resemble legitimate watch manufacturing.

Let’s take a look behind the curtain.

From “Fake” to “Factory-Grade”

Years ago, replicas were easy to spot:

- Wrong fonts

- Loud ticking quartz movements

- Lightweight cases

- Poor finishing

Today, the best factories operate almost like micro-brands. Some specialize only in:

- Rolex sports models

- Audemars Piguet cases

- Patek Philippe dials

- Tourbillon movements

Each component is often made in a different facility, then assembled elsewhere.

It’s more of a supply chain than a single workshop.

Step 1: Reverse Engineering the Original

High-end replica production usually starts with:

Buying an authentic watch: Rolex, Audemars Piguet, Patek Philippe, Richard Mille, Omega, etc.

Disassembling it completely

Measuring every component using digital calipers and 3D scanners

Factories analyze:

Case thickness

Lug shape

Dial texture

Hand length

Bezel teeth

Crown size

Bracelet taper

Some factories even weigh individual parts to match the original feel on the wrist.

Step 2: Case & Bracelet Manufacturing

Cases and bracelets are typically made using:

316L or 904L stainless steel

CNC machining

Hand polishing for edges and brushing

Higher-tier factories focus heavily on:

Sharp transitions between brushed and polished surfaces

Correct lug curvature

Smooth bracelet articulation

This is where cheap replicas fail — and premium ones stand out.

Step 3: Dial Creation (The Hardest Part)

Dials are notoriously difficult to replicate.

Factories must match:

Font thickness

Spacing

Color tone

Sunburst patterns

Lume application

A slight error in:

Logo position

Date window alignment

Marker angle

…can instantly expose a replica.

That’s why top factories remake dials repeatedly until the result is “close enough to fool the eye.”

Step 4: Movement Selection & Modification

Replica watches typically use:

Japanese Miyota movements

Asian ETA clones

Modified automatic calibers

Higher-end replicas modify movements to:

Match the hand stack height

Adjust beat rate

Align date change timing

Fit display casebacks accurately

Some movements are even decorated to visually resemble genuine Swiss calibers.

Step 5: Assembly & Quality Control

Final assembly includes:

Pressure testing

Hand alignment checks

Time regulation

Lume testing

Bezel rotation inspection

Top sellers reject batches that:

Have crooked indices

Loose crowns

Inconsistent date wheels

Poor bezel action

This step alone separates premium replicas from street-market fakes.

Why Some Replicas Cost $1,000+

People often ask:

“Why would anyone pay $800–$1,500 for a replica?”

Because you’re paying for:

Precision machining

Better materials

Improved movements

Skilled labor

Lower defect rates

It’s the difference between:

A $40 fashion watch

and

A carefully engineered mechanical timepiece.

The Collector Side of Replicas

Interestingly, some buyers:

Own genuine luxury watches

Use replicas for daily wear

Compare factory versions

Collect different generations of the same model

Replica collecting has become its own niche hobby.

Forums track:

Factory upgrades

Version numbers (V1, V2, V3…)

Dial improvements

Case corrections

It’s far more technical than most people realize.

Final Thoughts

Replica watches are no longer just “cheap fakes.”

At the high end, they are:

Engineered products

Built through specialized supply chains

Designed to closely match luxury originals

Whether someone agrees with replicas or not, the craftsmanship behind modern high-tier replicas is undeniably complex.

And now you know what really goes on behind the scenes.